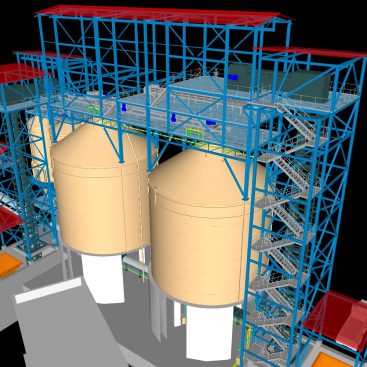

Project Name: PASARGAD Phase II Iron Smelting Material Handling System

Client: Zob Ahan-e PASARGAD

Contract Type: Engineering Services

Location: Shiraz – Fars / Iran

Contract Date: March 2017

About Project:

Zob Ahan-e PASARGAD company has been established with the aim of creating a complete steelmaking complex from the stage of receiving iron ore from the mine to the production of all kinds of alloy steels in

Fars province in the vicinity of Shiraz city.

The technology used in sponge iron units is MIDREX technology,

which is able to charge hot sponge iron to the melting furnace by applying the latest technological changes.

NSP Company has been responsible for designing the Material

Handling system of the Phase-II Irom smelting plant of this complex.

General Description of NSP Services:

– Feasibility studies of LAYOUT, PFD and P&ID designs.

– Designing tanks with 12,000t and 450t capacities for direct reduced

iron process.

– Designing Normal Belt and Side Wall Belt for direct reduced iron process.

– Lime, carbon, ferrosilicon and manganese storage tanks design.

– Preparing feeder, screen, winch, slider gate, etc. procurement documentations.

– Material handling system steel structures and foundations design

– Material handling system construction, installation, and commissioning supervision.

– Electrical equipment and instrument procurement engineering.

– Automation and instrument design documents.

– Installation and commissioning of material handling systems electricity and instrument.

Portfolio Description

- 1

- July 13, 2023

- Projects