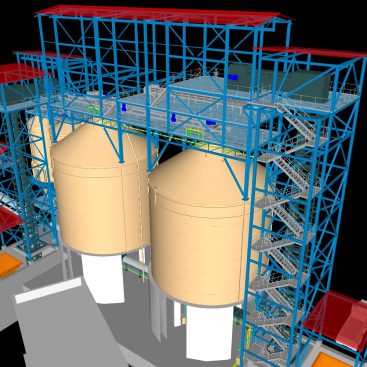

Project Name: Inspection and QC services for SSU & SRP Units of Ilam Complex

Client: Norahan Sanaye

Contract Type: Inspection & QC Services

Location: Ilam – Ilam / Iran

Contract Date: December 2020

About Project:

In order to refine the gas from the Tang Bijar and Kaman Kooh gas fields located in Ilam province, Ilam Gas Refinery Plant constructed.

NSP Company has cooperated as a consultant to Norahan company by doing Technical Inspection and quality assurance services of all steel structures and mechanical equipment.

General Description of NSP Services:

– Checking QCTM/QCP equipment construction.

– Supervising construction material laboratory testing and carrying out chemical and mechanical analysis of test results based on the relevant standards and code of practices.

– Inspection and supervising to assure quality of manufacturing and manufactured equipment of manufacturers.

– Participating quality control meetings of manufacturers.

– Inspection implementation of destructive and non-destructive tests during manufacturing.

– Checking compliancy of manufactured equipment with drawings,instructions and technical specifications of contract’s subject.

– Drafting inspection report and quality control forms.

– Evaluation and approval of quality control licenses.

– Closely monitoring device performance test.

– Inspection of packaging and protection of machined surfaces prone to impacts and damages.

– Checking and approving manufacturer’s produced Final Book.

Client: Norahan Sanaye

Contract Type: Inspection & QC Services

Location: Ilam – Ilam / Iran

Contract Date: December 2020

About Project:

In order to refine the gas from the Tang Bijar and Kaman Kooh gas fields located in Ilam province, Ilam Gas Refinery Plant constructed.

NSP Company has cooperated as a consultant to Norahan company by doing Technical Inspection and quality assurance services of all steel structures and mechanical equipment.

General Description of NSP Services:

– Checking QCTM/QCP equipment construction.

– Supervising construction material laboratory testing and carrying out chemical and mechanical analysis of test results based on the relevant standards and code of practices.

– Inspection and supervising to assure quality of manufacturing and manufactured equipment of manufacturers.

– Participating quality control meetings of manufacturers.

– Inspection implementation of destructive and non-destructive tests during manufacturing.

– Checking compliancy of manufactured equipment with drawings,instructions and technical specifications of contract’s subject.

– Drafting inspection report and quality control forms.

– Evaluation and approval of quality control licenses.

– Closely monitoring device performance test.

– Inspection of packaging and protection of machined surfaces prone to impacts and damages.

– Checking and approving manufacturer’s produced Final Book.